Dental implants have revolutionized the field of restorative dentistry, offering a durable and aesthetically pleasing solution for missing teeth. Central to the success of dental implants are the implant posts, which play a crucial role in supporting the replacement teeth. But what exactly are these posts made of? Understanding the materials used in dental implant posts helps elucidate why these implants are so effective and long-lasting.

Introduction to Dental Implant Posts

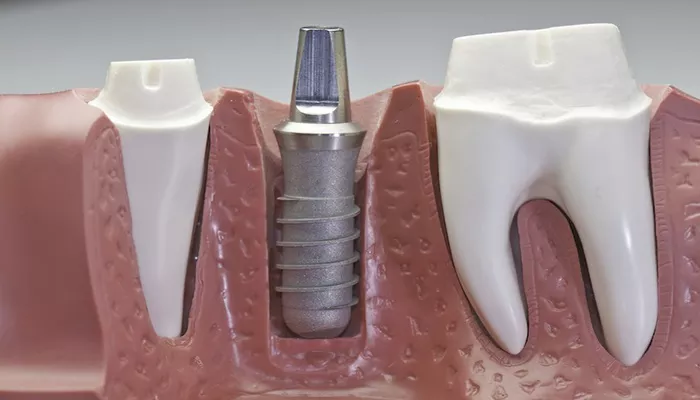

Dental implant posts are the components that are surgically placed into the jawbone to serve as a foundation for artificial teeth. These posts mimic the root of a natural tooth and provide the stability needed for the prosthetic tooth or crown to function effectively. The choice of material for these posts is critical as it affects the implant’s integration with the jawbone, its longevity, and the overall success of the implant procedure.

SEE ALSO: What Happens When A Dental Implant Falls Out?

Materials Used in Dental Implant Posts

Dental implant posts are typically made from several key materials, each offering unique properties that contribute to the success and durability of the implants. The primary materials used in dental implant posts include:

1. Titanium

Titanium is the most commonly used material for dental implant posts. Its popularity stems from its exceptional biocompatibility and strength. Here’s why titanium is a preferred choice:

Biocompatibility: Titanium is highly compatible with human bone, meaning it integrates well with the surrounding bone tissue. This property is crucial for osseointegration, where the implant fuses with the bone to provide a stable foundation for the artificial tooth.

Strength and Durability: Titanium is incredibly strong and can withstand the significant forces exerted during chewing and biting. This strength ensures that the implant remains intact and functional over time.

Corrosion Resistance: Titanium is resistant to corrosion, which is important for implants that are exposed to the moist environment of the mouth. This resistance helps in maintaining the integrity of the implant over years of use.

Lightweight: Despite its strength, titanium is relatively lightweight, which adds comfort to the patient and reduces any additional strain on the jawbone.

2. Titanium Alloys

While pure titanium is widely used, titanium alloys are also employed in dental implants. These alloys typically include elements such as aluminum and vanadium, which enhance certain properties of the titanium:

Increased Strength: Titanium alloys are often stronger than pure titanium, making them suitable for implants that require additional strength.

Improved Osseointegration: The addition of other metals can improve the surface characteristics of the implant, enhancing its ability to integrate with the bone.

3. Zirconia

Zirconia (zirconium dioxide) is a ceramic material that is increasingly used in dental implants, especially for those seeking a more aesthetic solution. Here’s why zirconia is a popular alternative to titanium:

Aesthetics: Zirconia implants are white and resemble the appearance of natural teeth. This makes them an attractive option for implants in visible areas where the metal appearance of titanium might be a concern.

Biocompatibility: Zirconia is also highly biocompatible, with excellent integration with the surrounding bone and tissue.

Strength: Zirconia is very strong and durable, though it is generally considered less flexible than titanium. It is still a viable option for many patients.

Corrosion Resistance: Like titanium, zirconia is resistant to corrosion and does not react with the oral environment.

4. Titanium-Zirconia Composites

In some cases, implants may be made from a combination of titanium and zirconia. These composites aim to combine the benefits of both materials:

Enhanced Strength and Aesthetics: The composite material offers the strength and durability of titanium while incorporating the aesthetic benefits of zirconia.

Reduced Risk of Allergic Reactions: Titanium-zirconia composites can reduce the risk of allergic reactions or sensitivities, making them a suitable option for patients with metal allergies.

The Manufacturing Process of Dental Implant Posts

The manufacturing of dental implant posts involves several sophisticated processes to ensure their precision, strength, and biocompatibility. Here’s an overview of the process:

1. Material Selection

The first step is selecting the appropriate material based on the patient’s needs and the implant’s intended function.

Factors such as the location of the implant, the patient’s bone quality, and aesthetic considerations play a role in material choice.

2. Design and Fabrication

Once the material is chosen, the implant post is designed using computer-aided design (CAD) software. The design is then translated into a physical implant using advanced manufacturing techniques such as:

CNC Machining: For titanium implants, CNC (computer numerical control) machining is used to precisely shape the implant from a titanium rod.

Sintering: Zirconia implants are often fabricated using a process called sintering, where zirconia powder is heated to high temperatures to form a solid ceramic material.

3. Surface Treatment

To enhance osseointegration, the surface of the implant is treated to improve its roughness and texture. Common surface treatments include:

Sandblasting: A method to roughen the surface, increasing its surface area and improving integration with the bone.

Anodization: For titanium implants, anodization can be used to create a thicker oxide layer that enhances biocompatibility.

Plasma Spraying: This technique can be used to apply a coating of calcium phosphate or other materials to improve bone integration.

4. Quality Control

Before the implants are approved for use, they undergo rigorous quality control testing to ensure they meet medical standards. This includes testing for strength, durability, and biocompatibility.

Conclusion

Dental implant posts are made from materials that offer a blend of strength, durability, and biocompatibility. Titanium, titanium alloys, zirconia, and titanium-zirconia composites each bring unique benefits to dental implantology. The choice of material is critical to the success of the implant, impacting everything from the integration with the jawbone to the aesthetics of the final restoration.