A recent study published in Scientific Reports investigates how primary human gingival fibroblasts and osteoblasts adhere to orthodontic mini-implants (OMIs) using scanning electron microscopy (SEM). The research aims to understand how the surface structure of these implants influences cell adhesion and growth, potentially leading to more effective and compatible orthodontic devices.

Background

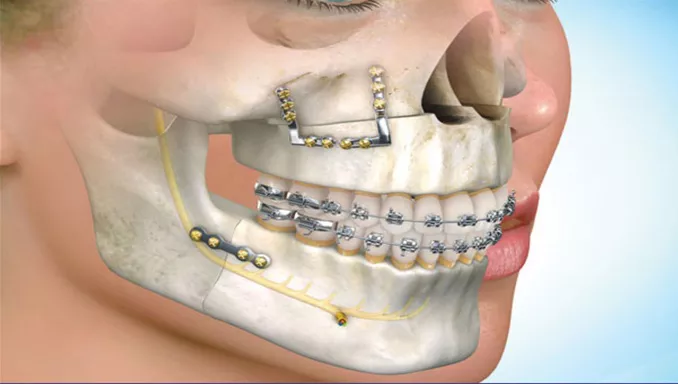

Orthodontic mini-implants (OMIs) are small titanium screws used in orthodontics to anchor tooth movement. Typically placed in the jawbone, OMIs serve as temporary anchors and consist of three parts: the head (for attaching dental appliances), the neck (for close contact with the mucosa), and the threaded body (for fixation in the bone).

Unlike permanent dental implants, OMIs are designed to avoid tissue in-growth, making them easier to remove. Made primarily from titanium alloys, OMIs are chosen for their corrosion resistance and bone compatibility. They often undergo surface treatments like ultraviolet (UV) light irradiation, which creates a superhydrophilic surface that enhances cell attachment and growth. However, OMIs rely on primary stability (macroretention) rather than secondary stability (osseointegration), ensuring they can be removed easily.

About The Research

The study focused on the adhesion of two cell types: primary gingival human fibroblasts and a human osteoblast cell line.

Researchers tested three commercially available OMIs: Tomas-pin, OrthoEasy Pin, and Dual Top G2, all made from the titanium alloy TiAl6V4, commonly used in orthopedic and dental implants.

The researchers used SEM and energy-dispersive X-ray (EDX) analysis to examine the surface microstructure and chemical composition of the OMIs. They then cultured the cells on the OMIs and observed their adhesion and growth patterns using SEM.

The process involved several steps: First, the OMIs were cleaned in 75% ethanol using an ultrasonic bath and sterilized at 121°C for 15 minutes. EDX analysis was performed to check the elemental composition of the OMIs. SEM then examined the microstructure of the OMIs at 500× magnification, focusing on the neck, thread, and head. Cells were cultured on the OMIs, TC coverslips (positive control), and poly(1,1,2,2-tetrafluoroethylene) (PTFE) (negative control) for comparison. Finally, SEM images were taken to evaluate cell adhesion to the OMIs.

Research Findings

SEM analysis revealed different surface structures, especially in the neck and thread areas of the OMIs. The Tomas-pin and OrthoEasy Pin had smooth neck areas, while the Dual Top G2 featured finely grooved structures. Although all threads had grooves, their continuity and sharpness varied between products.

Cell adhesion results showed that both fibroblasts and osteoblasts attached to all parts of the OMIs, with cells aligning parallel to the grooves on the threads. Cell density was higher on grooved threads compared to smooth neck areas. The OrthoEasy Pin, despite its anodized oxide layer, showed no significant difference in cell adhesion compared to other OMIs, suggesting that surface modifications did not notably impact cell response.

The microstructure of the implants also influenced cell shape and spreading. Cells aligned with the grooves, and higher cell density was observed on grooved surfaces, indicating a preference for microstructured surfaces.

Applications

These findings have implications for the design and optimization of OMIs. Cell adhesion to the OMI head is undesirable as it can lead to connective tissue overgrowth, a common issue. However, fibroblast adhesion to the neck is beneficial, helping to create a tight seal around the implant and reduce infection risk. Osteoblast adhesion to the thread area can improve stability by promoting bone attachment. However, excessive osseointegration could complicate removal. Therefore, the current OMI surface microstructure strikes a good balance, supporting osteoblast adhesion without complete osseointegration.